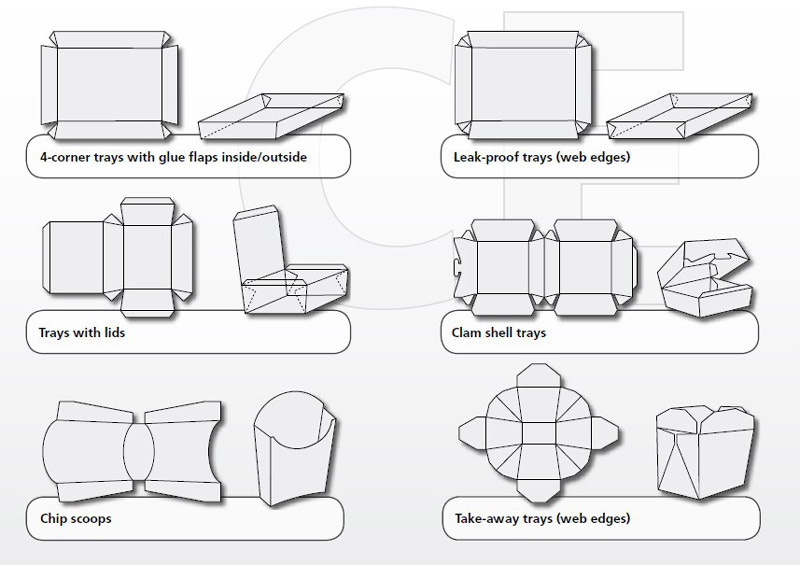

Burger boxes are an essential packaging solution for the food industry, designed to keep burgers fresh, safe and attractive. Burger boxes come in a variety of styles, including Clamshell trays, Quad trays with adhesive lids (inside/outside) and lidded trays, each with its own unique features. In addition, Box making machines also play a vital role in the efficient production of these containers.

1. Clamshell trays

Clamshell burger boxes are hinged containers that fold shut and have a secure and compact design. They are ideal for takeout and delivery due to their following features:

Secure closure – prevents spills and maintains food temperature.

Durable – Sturdy construction holds burgers securely.

Eco-friendly choice – Available in biodegradable materials.

2. Quad trays with adhesive lids (inside/outside)

These burger boxes have reinforced corners for extra stability. A glued lid (inside or outside) ensures a tight seal. Benefits include:

Enhanced structural integrity – prevents collapse during transport.

Customizable branding – large areas of printed logo.

Versatile – suitable for burgers, sandwiches and wraps.

3. Trays with lids

Burger boxes with lids offer convenience for stall owners and customers. They are commonly used in fast food chains and feature:

Easy-open lids – for quick access to food.

Stackability – for optimal storage and transport.

Ventilation options – perforated to prevent moisture.

Modern burger box production relies on automatic paper carton erecting forming machine, which streamline the production process by:

High-speed production – thousands of boxes can be produced per hour.

Precision folding and gluing – ensure consistent box quality.

Customization – can be adapted to different sizes and styles (clamshell, four-corner, etc.).

These machines reduce labor costs and increase efficiency, making them a must-have for large food packaging suppliers.

Conclusion

Burger boxes come in a variety of designs, each of which meets different needs - whether it is safe to take away (clamshell), enhanced stability (quad tray) or convenient to carry (lid tray). With advanced Box Forming Machine, manufacturers can efficiently produce high-quality, customizable packaging.

For restaurants and food companies, choosing the right burger box can improve customer satisfaction while ensuring that food remains fresh and intact. Investing in the right packaging solution is essential for delivery and presentation.

GET A QUOTE