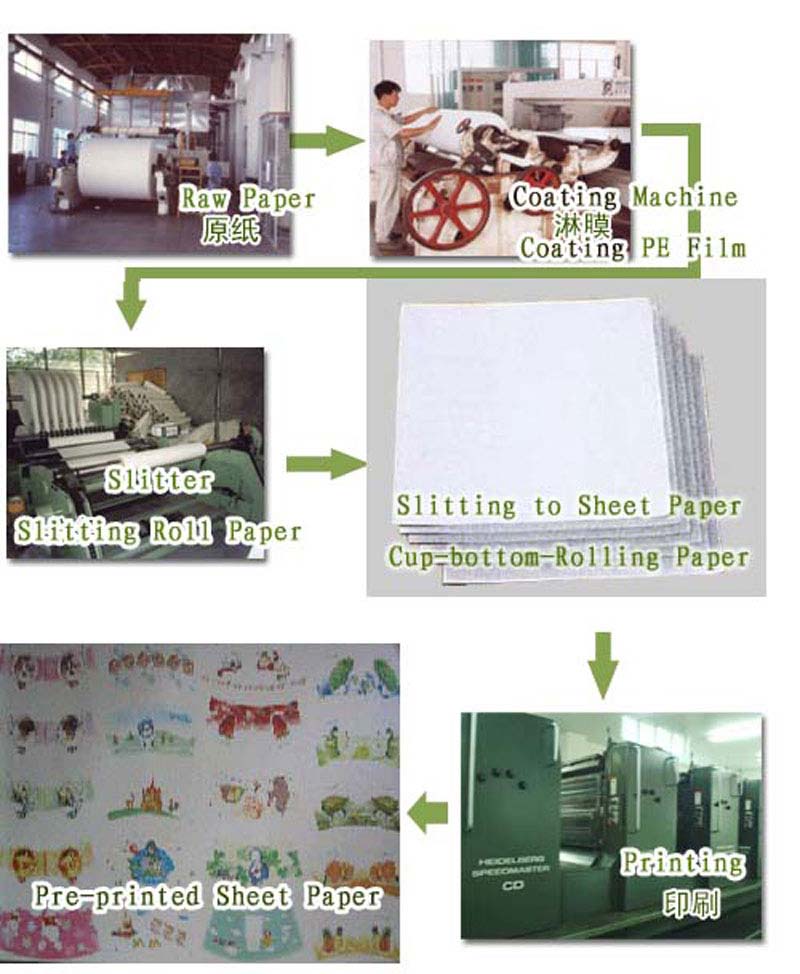

Explain:

From the above image,you can know that the whole line include the following process:

1.PE Coating : Use PE-Coating Machine Coating PE film on raw white paper; Coating one side name Single Side PE Coated Paper; Coating two sides name Double Sides PE Coated Paper

2.Slitting : Use Slitter slitting PE Coated Rolling Paper to [ sheet paper(make cup body) ] and [ cup-bottom rolling paper ].

3.Printing : Use Printing Machine printing all kinds of design on the sheet paper

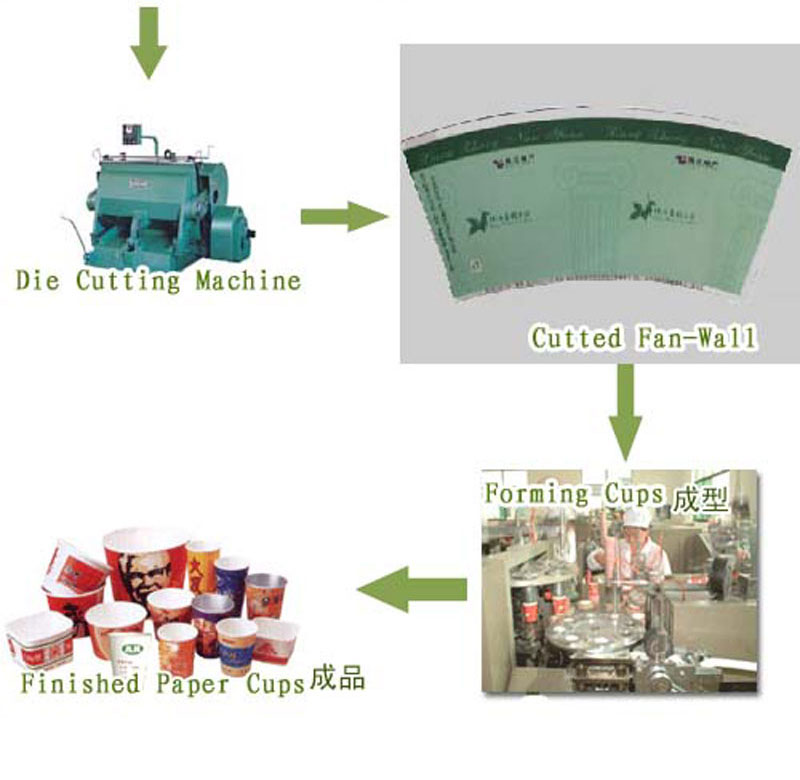

4.Die Cutting : Use Die Cutting Machine cut the Pre-printed sheet paper to cup-fan-wall body

5.Forming Paper Cups : Use Paper Cup Forming Machine or Paper Bowl Forming Machine auto make paper cups,paper bowls. One worker is enough for forming machine, only need operator put the cup-fan-wall body to the entrance and the rolling-bottom to the bottom entrance, and then take the finished cups out.

6.Packaging : Pack the finished paper cups in plastic bags ,and then bags to cardboard box.

Note :

The above process show the whole line, so for customers:

Buy PE Coated Sheet Paper and Cup-bottom-roll Paper from the PE Film Paper Suppliers(The PE Coated paper suppliers do the process of PE coating, slitting)

Then printing on sheet paper and cut the sheet paper to cup-fan-wall body

Final: use forming machine to produce paper cups

Recommend:

Some PE Coated Paper Suppliers also offer the services of pre printing and pre cutting, so you can buy the cup-fan-wall body and the cup-bottom-roll paper from the paper suppliers;

IF you are first time in this project, Only do the forming process, that mean only buy the paper cup forming machine, for the cost of pre printing and pre cutting is very cheap(you can finish those process out-side in Printing Company or others).

You also can buy a die cutting machine,and do this process yourself.

If you want to do the printing step: you can select the offet printer or felxo printer,and other printers can be used on the PE coated paper.

GET A QUOTE