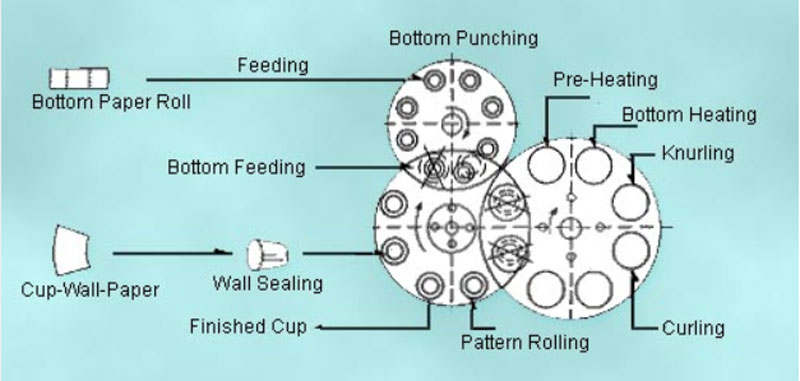

Explain:

From the above picture,you can get that to the process of making paper cups(bowls,buckets) in our machines:

1.Feed the pre printing and pre cutting cup-fan-wall paper to the entrance;

2.Feed the rolling cup-bottom paper to the entrance;

3.The cup-fan-wall paper auto sealing on the body sealing mold >>>become cone shape, the cup-bottom auto punching(cutting) in the machine

4.After pre-heating, bottom heating, then the cup-bottom knurling to the cup cone body;

5.Curling process: curling the cup top to circular shape;

6.Pattern rolling, in here, you can add another system to send the finished paper cups to the working desk;

7.Package the finished paper cups in plactic bag or other hermetic bags to protect the cup top shape becoming ugly or breached

8.Package the plastic bags in a cardboard box....

Note:the process of making paper bowls,paper buckets are the same as making paper cups.

Mechanical :

The general structure of paper cup(bowl) shaping machine is composed of fice parts.They are the first stage,the medium stage,the second stage,the third stage and its outer shell.

1.The first stage:mainly finishes transmission of the paper cup's side-wall paper,shaping side-wall and transferring them to the mediun stage after shaped;

2.The medium stage:mainly finishes transmission of the cup-bottom paper,shaping cup-bottom,joining the shaped side-wall and cup-bottom,automatic transmission and discharging of the shaped cup,and curling the shaped cup's edge;

3.The third stage:mainly includes 45 angle separating,preheating,curing bottom,rouletting,curling rim and so on mechanisms,which are the important parts in finishing paper cup;

4.The fourth stage:mainly includes motor,reduction gear and so on.A frequency converter is used to finish adjusting its speed and providing power.

GET A QUOTE